Create Time: 11 ,13 ,2024

The milking parlor is the heart of a dairy farm, directly impacting milk yield and quality. Cows pass through it 2–3 times a day, and with a high cow density in the waiting area (just 1.6–2㎡ per cow), managing temperature and humidity becomes more challenging than in other barns. To ensure optimal conditions year-round, especially during extreme heat or cold, effective ventilation, cooling, and heating systems are essential. The focus should be on the waiting area and the milking machine zones.

Summer Ventilation and Cooling

In summer, aim for an air exchange rate of 6–9 air changes per minute in the milking parlor.

Ventilation and Cooling in the Waiting Area

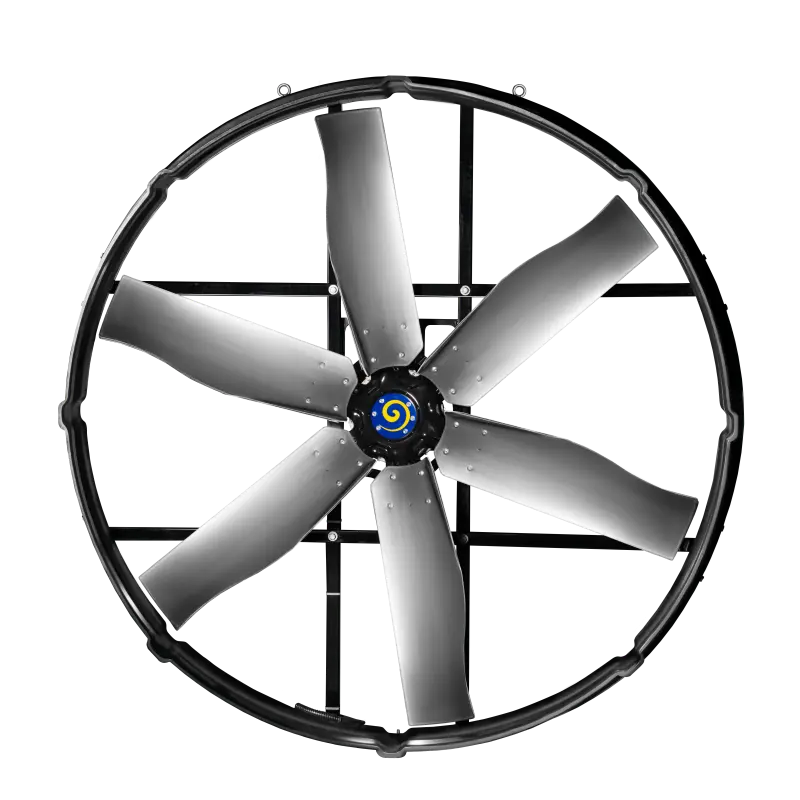

Given the high cow density, the waiting area requires special attention during hot, humid weather. Typically, circulation fans provide additional ventilation, and in some cases, cooling systems like soaking setups may be needed.

When using industrial ventilation systems, circulation ventilation is key, particularly if the waiting area is adjacent to the barn. This prevents polluted air from being drawn into the waiting area and ensures that dirty air in the waiting area isn’t pulled into the milking machine zone.

Cooling at the Milking Machine Zone

At the milking machine zone, circulation ventilation is also recommended. Installing fans along the gable walls to direct airflow toward the machines is an effective way to cool the space.

As temperatures in the milking pit rise during summer, improving airflow is crucial to lower the temperature and enhance comfort for the milking staff. Ceiling fans with downward airflow can help achieve this by boosting air circulation in the pit.

Winter Ventilation and Heating

In winter, aim for an air exchange rate of 0.1–0.15 air changes per minute in the milking parlor.

Ventilation and Heating in the Waiting Area

The main goal of winter ventilation in the waiting area is to remove moisture from the cows. Natural ventilation typically relies on ridge and eave vents, but if additional ventilation is needed, circulation fans should be used to avoid pulling polluted air into the milking machine zone.

In particularly cold conditions, the waiting area should be sealed and heated to prevent the floor from freezing, which could lead to slips and injuries.

Ventilation and Heating at the Milking Machine Zone

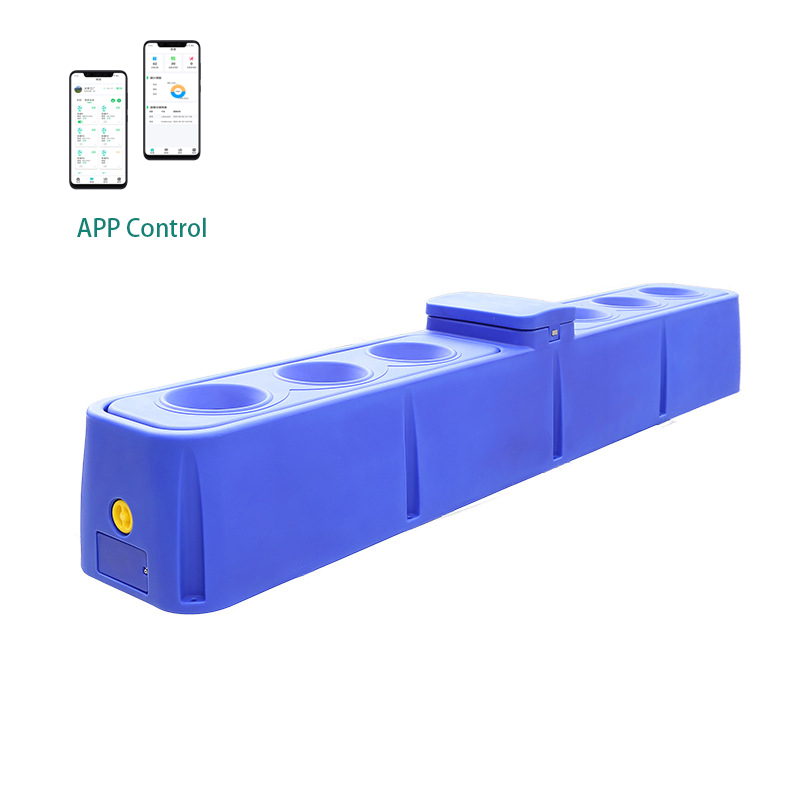

In winter, doors and windows are often kept tightly closed, so the exhaust fan for dairy farm is essential for removing excess humidity. These fans should be placed downwind and directed outside, away from the milk reception area, waiting zone, and office to prevent recirculating contaminated air.

Heating at the milking machine zone is also critical. Proper insulation helps retain the heat generated by cows during milking, reducing the need for additional heating. When necessary, infrared heaters, underfloor heating, or air conditioning can be used, especially when milking isn't in progress or when outdoor temperatures are extremely low.

English

English  中文

中文